Technology & Quality

Commitment to Quality and Customer Service

Imaflex management is committed to taking a leadership role in developing and maintaining quality products through on-going training, consistent testing, and the ISO philosophy.

Certifications

Industry-Leading Accreditations

Our certifications demonstrate our unwavering commitment to quality, safety, and regulatory compliance across all operations.

FSSC 22000

Food Safety System Certification ensuring the highest standards in food packaging safety and quality management.

ISO 9001:2015

International standard for quality management systems, demonstrating our commitment to consistent quality.

Hazard Analysis Critical Control Point Certification at Imaflex U.S.A.

Customs-Trade Partnership Against Terrorism certified.

U.S. Postal Services approved supplier.

Interstate Milk Shippers certification.

FDA approved and Health Canada no objection status.

Our Facilities

State-of-the-Art Manufacturing

Manufacturing

Advanced Film Extrusion

Quality Control

Real-Time Monitoring

Analysis

Precision Testing

Capabilities

Advanced Technology & Expertise

Our investment in technology and talent ensures we deliver consistent, high-quality products that meet the most demanding specifications.

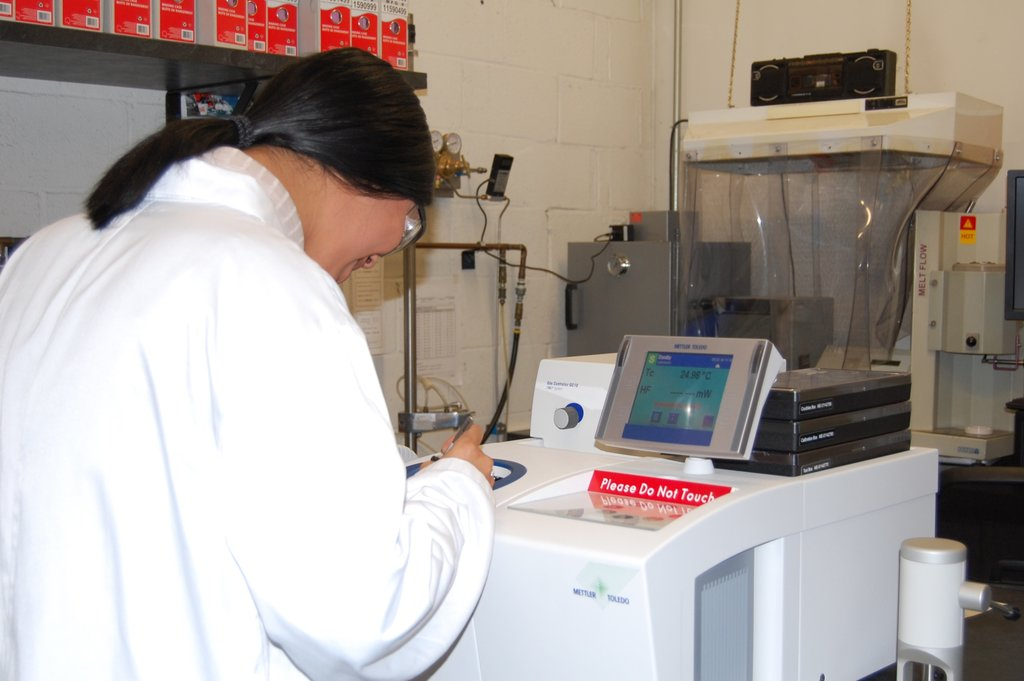

Analytical Laboratory

Our lab is equipped with reliable, accurate testing instruments under controlled ambient conditions of temperature and relative humidity according to ASTM and ISO standards.

Real-Time Quality Control

Computerized workstations and state-of-the-art control equipment enable product quality to be controlled and monitored in real time for immediate corrective action.

Custom Additive Concentrates

We create and manufacture additive concentrates tailored to specific applications for all polyolefin film products produced in our facilities.

Product Development

Our team of product development engineers review customer applications and assist in determining the film characteristics best suited for particular applications.

Our Commitment

“Certificates of analysis generated in our lab can be provided covering various physical, mechanical and surface properties of our different products.”

Testing is achieved under controlled ambient conditions of temperature and relative humidity according to ASTM and ISO standards.